Name of Process:

Friction Stir Welding (FSW)

Key Features:

- A solid-state welding process that joins materials without melting them.

- Uses a rotating tool to generate frictional heat and mechanically mix materials.

- Produces high-strength, defect-free welds.

- Suitable for materials that are difficult to weld using traditional methods.

Applications:

- Aerospace (e.g., aircraft fuselages, fuel tanks).

- Automotive (e.g., lightweight aluminum components).

- Shipbuilding (e.g., hulls and decks).

- Railway and construction industries.

- Electronics (e.g., heat sinks and enclosures).

Recommended Tools and Equipment:

- FSW machine (manual or CNC-controlled).

- Rotating tool with a shoulder and pin (made of durable materials like tool steel).

- Clamping system to secure workpieces.

- Cooling system (if required for specific materials).

- Safety gear (gloves, goggles, and protective clothing).

Setup and Settings:

- Select the appropriate tool design and material for the workpiece.

- Secure the workpieces firmly to prevent movement during welding.

- Set the tool rotation speed, travel speed, and plunge depth based on material type and thickness.

- Calibrate the machine for consistent weld quality.

Technique Tips:

- Ensure proper alignment and fit-up of the workpieces.

- Use consistent tool rotation and travel speeds for uniform welds.

- Monitor tool wear and replace as needed to maintain weld quality.

- Optimize parameters (e.g., rotation speed, plunge depth) for specific materials.

Common Challenges and Solutions:

- Challenge: Tool wear or breakage.

Solution: Use high-quality tools and monitor wear regularly. - Challenge: Incomplete penetration or weak welds.

Solution: Adjust tool plunge depth and travel speed. - Challenge: Material distortion or cracking.

Solution: Optimize clamping and welding parameters.

Safety Considerations:

- Wear heat-resistant gloves, safety goggles, and protective clothing.

- Ensure proper ventilation to avoid inhaling fumes or dust.

- Regularly inspect equipment for wear or damage.

- Follow lockout/tagout procedures during maintenance.

- Keep a fire extinguisher nearby for emergencies.

1. What is Friction Stir Welding (FSW)?

Direct Response:

Friction Stir Welding (FSW) is a solid-state welding process that joins materials without melting them, using a rotating tool to generate frictional heat and mechanically mix the materials.

Detailed Explanation:

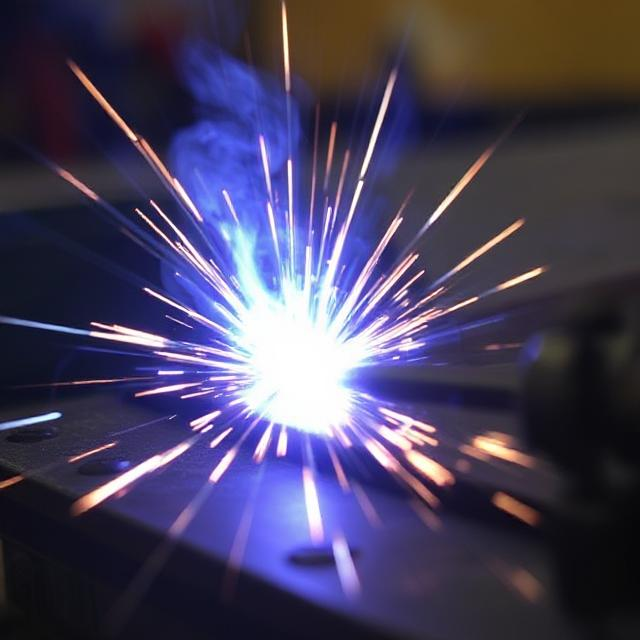

FSW involves a rotating tool with a shoulder and pin that plunges into the joint between two workpieces. The tool generates frictional heat, softening the material, and mechanically stirs it to create a strong, defect-free weld.

Example:

In aerospace manufacturing, FSW is used to join aluminum alloy panels for aircraft fuselages, ensuring lightweight and high-strength welds.

Additional Resources:

2. How does Friction Stir Welding work?

Direct Response:

FSW uses a rotating tool to generate frictional heat and mechanically mix materials, creating a solid-state weld without melting.

Detailed Explanation:

The tool rotates and moves along the joint line, generating heat through friction. The softened material is mechanically mixed by the tool’s pin, creating a strong bond as it cools.

Example:

A robotic FSW system might weld aluminum sheets for a ship’s hull, producing consistent, high-quality welds in minutes.

3. What materials can be welded using FSW?

Direct Response:

FSW is primarily used for welding aluminum, magnesium, and other non-ferrous metals, as well as some steels and composites.

Detailed Explanation:

FSW is ideal for materials that are difficult to weld using traditional methods, such as high-strength aluminum alloys. It can also weld dissimilar materials, like aluminum to steel.

Example:

A railway manufacturer might use FSW to join aluminum panels for lightweight train carriages.

4. What are the advantages of FSW?

Direct Response:

FSW offers high-strength welds, no melting, and the ability to weld difficult materials, making it ideal for aerospace, automotive, and shipbuilding.

Detailed Explanation:

FSW produces defect-free welds with minimal distortion, no filler materials, and excellent mechanical properties. It’s also environmentally friendly, as it doesn’t produce fumes or spatter.

Example:

In automotive manufacturing, FSW is used to join aluminum components, reducing vehicle weight and improving fuel efficiency.

5. What equipment is needed for FSW?

Direct Response:

Key equipment includes an FSW machine, rotating tools, a clamping system, and safety gear.

Detailed Explanation:

The FSW machine provides the rotational and translational motion, while the rotating tool (with a shoulder and pin) generates heat and mixes the material. A clamping system secures the workpieces, and safety gear protects the operator.

Example:

A shipbuilding company might use a large CNC-controlled FSW machine with water-cooled tools for welding aluminum hulls.

6. How do I set up and adjust an FSW machine?

Direct Response:

Set up involves selecting the right tool, securing the workpieces, and adjusting rotation speed, travel speed, and plunge depth.

Detailed Explanation:

Start by cleaning and aligning the workpieces. Choose a tool design suitable for the material and joint type. Set the machine parameters (e.g., 500–2000 RPM rotation speed, 50–500 mm/min travel speed) based on material thickness and type.

Example:

For welding 6mm aluminum sheets, you might set the rotation speed to 1000 RPM, travel speed to 200 mm/min, and plunge depth to 6.2mm.

7. What are common issues in FSW and how do I fix them?

Direct Response:

Common issues include tool wear, incomplete penetration, and material distortion, which can be fixed by adjusting parameters or maintaining equipment.

Detailed Explanation:

- Tool wear: Use high-quality tools and monitor wear regularly.

- Incomplete penetration: Increase plunge depth or reduce travel speed.

- Material distortion: Optimize clamping and welding parameters.

Example:

If welds are weak, increase the plunge depth or rotation speed slightly and test again.

8. What safety precautions should I take with FSW?

Direct Response:

Wear protective gear, ensure proper ventilation, and follow equipment maintenance protocols.

Detailed Explanation:

Protective gear includes heat-resistant gloves, safety goggles, and flame-resistant clothing. Ensure the workspace is well-ventilated to avoid inhaling dust or fumes, and regularly inspect equipment for wear or damage.

Example:

An operator should always wear gloves and goggles when using an FSW machine to protect against heat and moving parts.

9. Can FSW be automated?

Direct Response:

Yes, FSW can be automated using CNC-controlled or robotic systems for high-volume production.

Detailed Explanation:

Automated FSW systems are common in industries like aerospace and automotive, where precision and repeatability are critical. These systems use programmable machines to perform consistent, high-quality welds.

Example:

An aircraft manufacturer might use robotic FSW arms to weld aluminum panels for fuselages, ensuring consistent quality and reducing production time.

10. What industries use FSW?

Direct Response:

FSW is widely used in aerospace, automotive, shipbuilding, and railway industries.

Detailed Explanation:

FSW’s ability to produce high-strength, lightweight welds makes it ideal for industries requiring durable and efficient joining methods.

Example:

In shipbuilding, FSW is used to join aluminum panels for hulls and decks, reducing weight and improving fuel efficiency.