Name of Process

Gas Metal Arc Welding (GMAW), commonly known as “MIG Welding” (Metal Inert Gas).

Key Features

- Uses a continuous wire electrode fed through a welding gun.

- Requires shielding gas (e.g., argon, CO2, or a mix) to protect the weld pool.

- High welding speed and efficiency.

- Suitable for a wide range of metals, including steel, aluminum, and stainless steel.

- Easy to learn and ideal for beginners.

Applications

- Automotive repair and manufacturing.

- Fabrication of metal structures and equipment.

- DIY projects and home repairs.

- Industrial manufacturing and production lines.

Recommended Tools and Equipment

- MIG welding machine (with wire feed system).

- Shielding gas cylinder (argon, CO2, or mixed gas).

- Welding gun and consumable wire electrode.

- Welding helmet with auto-darkening lens.

- Gloves, apron, and protective clothing.

- Wire brush and grinder for cleaning.

Setup and Settings

- Choose the correct wire electrode and shielding gas for the material.

- Set the wire feed speed and voltage according to material thickness.

- Ensure proper gas flow rate (typically 20-25 CFH).

- Ground the workpiece securely.

- Adjust the welding gun nozzle and contact tip for optimal performance.

Technique Tips

- Maintain a consistent travel speed and gun angle (15-20 degrees).

- Use a push technique for better visibility and cleaner welds.

- Keep the wire electrode extension (stick-out) around 1/4 to 3/8 inch.

- Clean the workpiece thoroughly before welding.

Common Challenges and Solutions

- Porosity: Caused by inadequate shielding gas. Check gas flow and avoid drafts.

- Burn-Through: Prevent by reducing voltage or increasing travel speed on thin metals.

- Wire Feeding Issues: Clean the liner and ensure proper tension on the drive rolls.

- Spatter: Minimize by adjusting voltage and using anti-spatter spray.

Safety Considerations

- Wear proper PPE (helmet, gloves, flame-resistant clothing).

- Work in a well-ventilated area or use fume extraction to avoid inhaling harmful gases.

- Beware of electric shock; inspect cables and connections.

- Keep a fire extinguisher nearby and clear the work area of flammable materials.

1. What is MIG welding, and how does it work?

Direct Response:

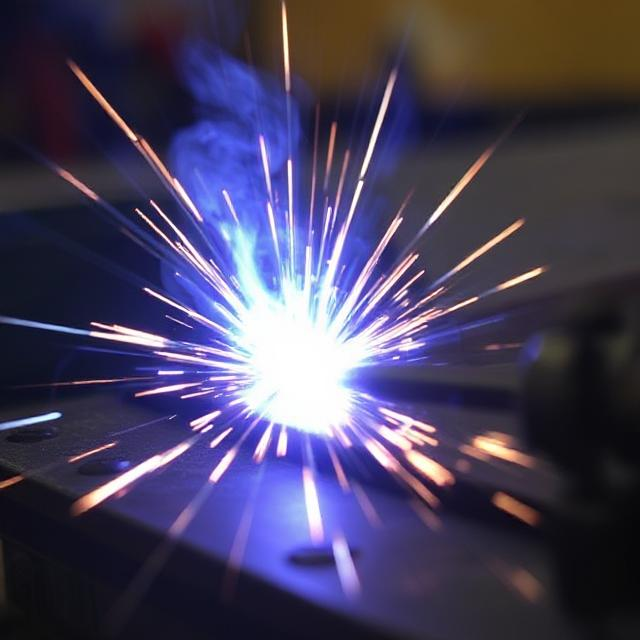

MIG welding (Gas Metal Arc Welding or GMAW) is a process that uses a continuous wire electrode and shielding gas to create an electric arc, melting the metal and forming a weld.

Detailed Explanation:

The wire electrode is fed through a welding gun, and the shielding gas (e.g., argon, CO2) protects the weld pool from contamination. The arc melts the wire and the base metal, creating a strong bond.

Examples or Case Studies:

- Used in automotive manufacturing for body repairs.

- Commonly used in fabrication shops for building metal structures.

Additional Resources:

- Video tutorial: “How MIG Welding Works.”

- Article: “The Science Behind Gas Metal Arc Welding.”

2. What types of metals can be welded with MIG welding?

Direct Response:

MIG welding can weld steel, stainless steel, aluminum, and other non-ferrous metals.

Detailed Explanation:

- Steel: Use a solid wire electrode with CO2 or mixed gas.

- Stainless Steel: Use stainless steel wire with a tri-mix gas (argon, CO2, oxygen).

- Aluminum: Use aluminum wire with 100% argon gas.

Examples or Case Studies:

- Aluminum MIG welding is used in boat building and aerospace.

- Steel MIG welding is common in construction and automotive repair.

Additional Resources:

- Guide: “Choosing the Right Wire and Gas for MIG Welding.”

- Video: “MIG Welding Different Metals.”

3. What shielding gas should I use for MIG welding?

Direct Response:

The shielding gas depends on the material:

- Steel: CO2 or a mix of 75% argon and 25% CO2.

- Stainless Steel: Tri-mix gas (argon, CO2, oxygen).

- Aluminum: 100% argon.

Detailed Explanation:

Shielding gas prevents contamination and stabilizes the arc. Using the wrong gas can lead to poor weld quality.

Examples or Case Studies:

- A fabrication shop improved weld quality by switching to a 75/25 argon/CO2 mix for steel.

Additional Resources:

- Shielding gas selection chart.

- Article: “Understanding Shielding Gases for MIG Welding.”

4. How do I set the correct wire feed speed and voltage?

Direct Response:

Refer to the welding machine’s manual or a welding chart for recommended settings based on material thickness and wire diameter.

Detailed Explanation:

- Wire Feed Speed: Controls the amount of filler metal deposited.

- Voltage: Determines the heat input and arc stability.

Examples or Case Studies:

- A beginner achieved better welds after adjusting the wire feed speed to match the material thickness.

Additional Resources:

- Welding parameter chart.

- Video: “Setting Up Your MIG Welder.”

5. Can MIG welding be used outdoors?

Direct Response:

MIG welding can be used outdoors, but wind can disperse the shielding gas, leading to porosity. Use flux-cored wire for outdoor welding.

Detailed Explanation:

Flux-cored wire creates its own shielding, making it ideal for outdoor use.

Examples or Case Studies:

- Construction crews use flux-cored MIG welding for outdoor structural projects.

Additional Resources:

- Guide: “Outdoor Welding Tips for MIG Welding.”

- Video: “MIG Welding in the Field.”

6. What are the advantages of MIG welding over other methods?

Direct Response:

MIG welding is fast, easy to learn, and versatile, making it ideal for beginners and professionals.

Detailed Explanation:

- Speed: Continuous wire feed allows for faster welding.

- Ease of Use: Less skill required compared to TIG or stick welding.

- Versatility: Can weld a variety of metals and thicknesses.

Examples or Case Studies:

- MIG welding is the preferred method for automotive repair due to its speed and ease.

Additional Resources:

- Article: “MIG vs. TIG vs. Stick Welding: Which is Right for You?”

- Video: “Advantages of MIG Welding.”

7. How do I prevent porosity in MIG welds?

Direct Response:

Prevent porosity by ensuring proper gas flow, cleaning the workpiece, and avoiding drafts.

Detailed Explanation:

Porosity is caused by contaminants or inadequate shielding. Check gas hoses for leaks and clean the metal surface before welding.

Examples or Case Studies:

- A welder eliminated porosity by increasing the gas flow rate and cleaning the metal.

Additional Resources:

- Guide: “Common Weld Defects and How to Fix Them.”

- Video: “Preventing Porosity in MIG Welds.”

8. What safety gear is required for MIG welding?

Direct Response:

Essential safety gear includes a welding helmet, gloves, flame-resistant clothing, and safety boots.

Detailed Explanation:

- Helmet: Protects eyes from UV/IR radiation.

- Gloves: Insulate against heat and electric shock.

- Clothing: Prevents burns from sparks and molten metal.

- Boots: Protect feet from falling objects.

Examples or Case Studies:

- A welder avoided severe burns by wearing a flame-resistant jacket.

Additional Resources:

- Checklist: “Essential Welding Safety Gear.”

- Video: “Welding Safety Tips for Beginners.”

9. What are the most common mistakes beginners make with MIG welding?

Direct Response:

Common mistakes include incorrect settings, poor gun angle, and failing to clean the workpiece.

Detailed Explanation:

- Incorrect Settings: Leads to weak or inconsistent welds.

- Poor Gun Angle: Causes uneven bead appearance.

- Dirty Workpiece: Results in porosity and weak welds.

Examples or Case Studies:

- A beginner improved their welds significantly after learning to clean the metal properly.

Additional Resources:

- Guide: “Top 10 MIG Welding Mistakes and How to Avoid Them.”

- Video: “Beginner MIG Welding Tips.”

10. How do I troubleshoot wire feeding issues?

Direct Response:

Check for blockages in the liner, ensure proper tension on the drive rolls, and use the correct wire diameter.

Detailed Explanation:

Wire feeding issues can be caused by a dirty liner, incorrect drive roll tension, or using the wrong size wire.

Examples or Case Studies:

- A welder resolved feeding issues by cleaning the liner and adjusting the drive roll tension.

Additional Resources:

- Guide: “Troubleshooting MIG Welding Wire Feed Problems.”

- Video: “Fixing Wire Feeding Issues.”